-

1 Litre SuperClean Jewellery Cleaner | Ultrasonic Fluid

In stock£15.99 £13.33 (ex. VAT)Unit price /Unavailable -

5 Litre SuperClean Jewellery Cleaner | Ultrasonic Fluid

In stock£34.99 £29.16 (ex. VAT)Unit price /Unavailable -

-

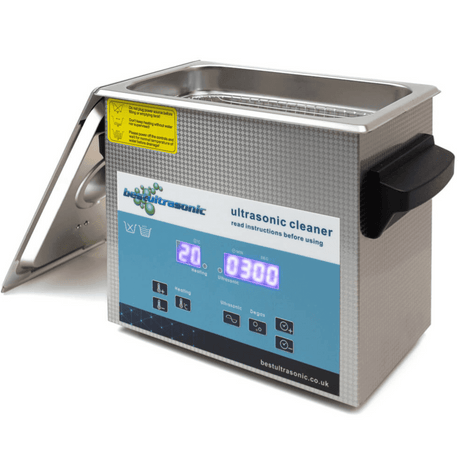

2 Litre Ultrasonic Jewellery Cleaner | Digital | Degassing

In stock£89.99 £74.99 (ex. VAT)Unit price /Unavailable -

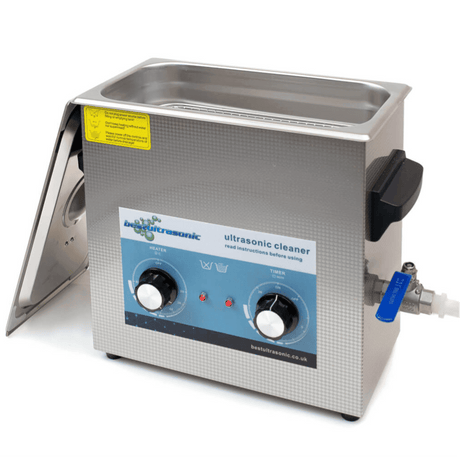

3 Litre Ultrasonic Jewellery Cleaner | Dial Control

In stock£139.99 £116.66 (ex. VAT)Unit price /Unavailable -

3 Litre Ultrasonic Cleaner | Adjustable Power

In stock£159.99 £133.33 (ex. VAT)Unit price /Unavailable -

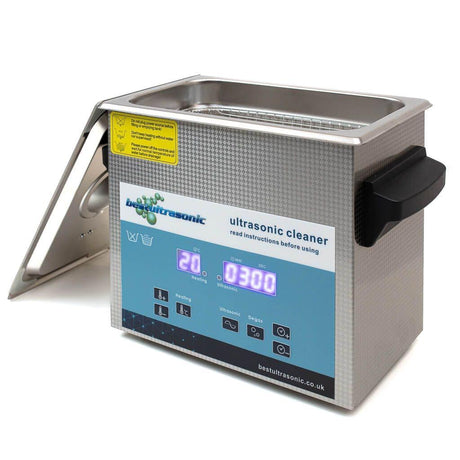

3 Litre Ultrasonic Jewellery Cleaner | Digital | Degassing

In stock£199.99 £166.66 (ex. VAT)Unit price /Unavailable -

6 Litre Ultrasonic Jewellery Cleaner | Dial Control

In stock£229.99 £191.66 (ex. VAT)Unit price /Unavailable -

6 Litre Ultrasonic Cleaner | Adjustable Power

In stock£269.99 £224.99 (ex. VAT)Unit price /Unavailable -

6 Litre Ultrasonic Jewellery Cleaner | Digital | Degassing

In stock£269.99 £224.99 (ex. VAT)Unit price /Unavailable -

10 Litre Ultrasonic Jewellery Cleaner | Dial Control

In stock£289.99 £241.66 (ex. VAT)Unit price /Unavailable -

10 Litre Ultrasonic Jewellery Cleaner | Digital | Degassing

In stock£369.99 £308.33 (ex. VAT)Unit price /Unavailable

Our Best Selling Products

-

5 Litre Carburettor & Engine Cleaner | Ultrasonic Fluid

In stock£29.99 £24.99 (ex. VAT)Unit price /Unavailable -

Ultrasonic Cleaner - Dental Instruments (3 litre)

In stock£139.99 £116.66 (ex. VAT)Unit price /Unavailable -

3 Litre Ultrasonic Cleaner | Digital | Degassing

In stock£199.99 £166.66 (ex. VAT)Unit price /Unavailable -

6 Litre Ultrasonic Cleaner | Dial Control

In stock£229.99 £191.66 (ex. VAT)Unit price /Unavailable -

6 Litre Ultrasonic Jewellery Cleaner | Digital | Degassing

In stock£269.99 £224.99 (ex. VAT)Unit price /Unavailable -

1 Litre Carburettor & Engine Cleaner | Ultrasonic Fluid

In stock£12.99 £10.83 (ex. VAT)£13.99Unit price /Unavailable -

1 Litre SuperClean Jewellery Cleaner | Ultrasonic Fluid

In stock£15.99 £13.33 (ex. VAT)Unit price /Unavailable